Our technical innovation never stops.

Mainly developed products for Smart Factories

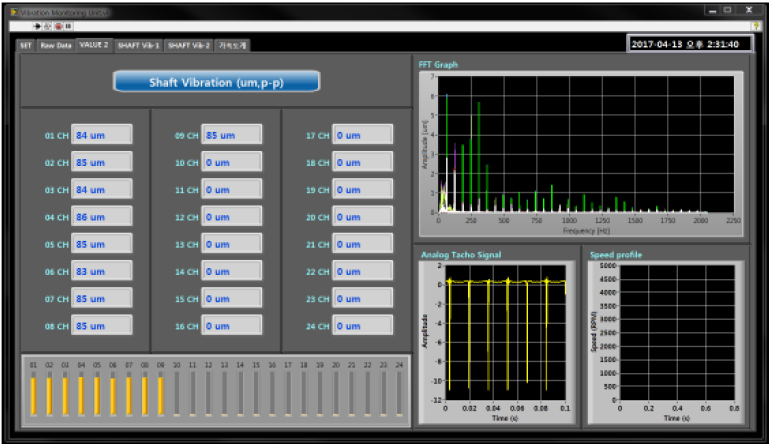

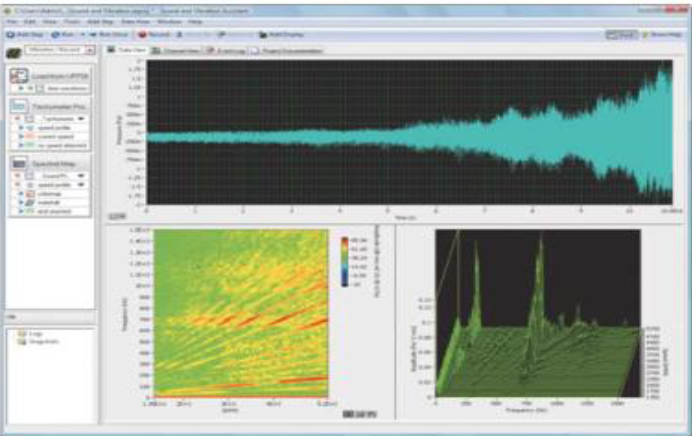

VMS(Vibration Monitoring System) and IO Sensor Module

- 1) Vibration sensor (Imported product) : AC level signals of displacement, speed, and acceleration sensors

- 2) Signal collector (Self-development) : Signal input terminal and LAN port

- 3) Switch & PC (Product in the marketplace) : PoE Switch Hub, Personal Computer

- 4) VMS program (Self-development) : Monitoring, recording, and analyzing vibration signals

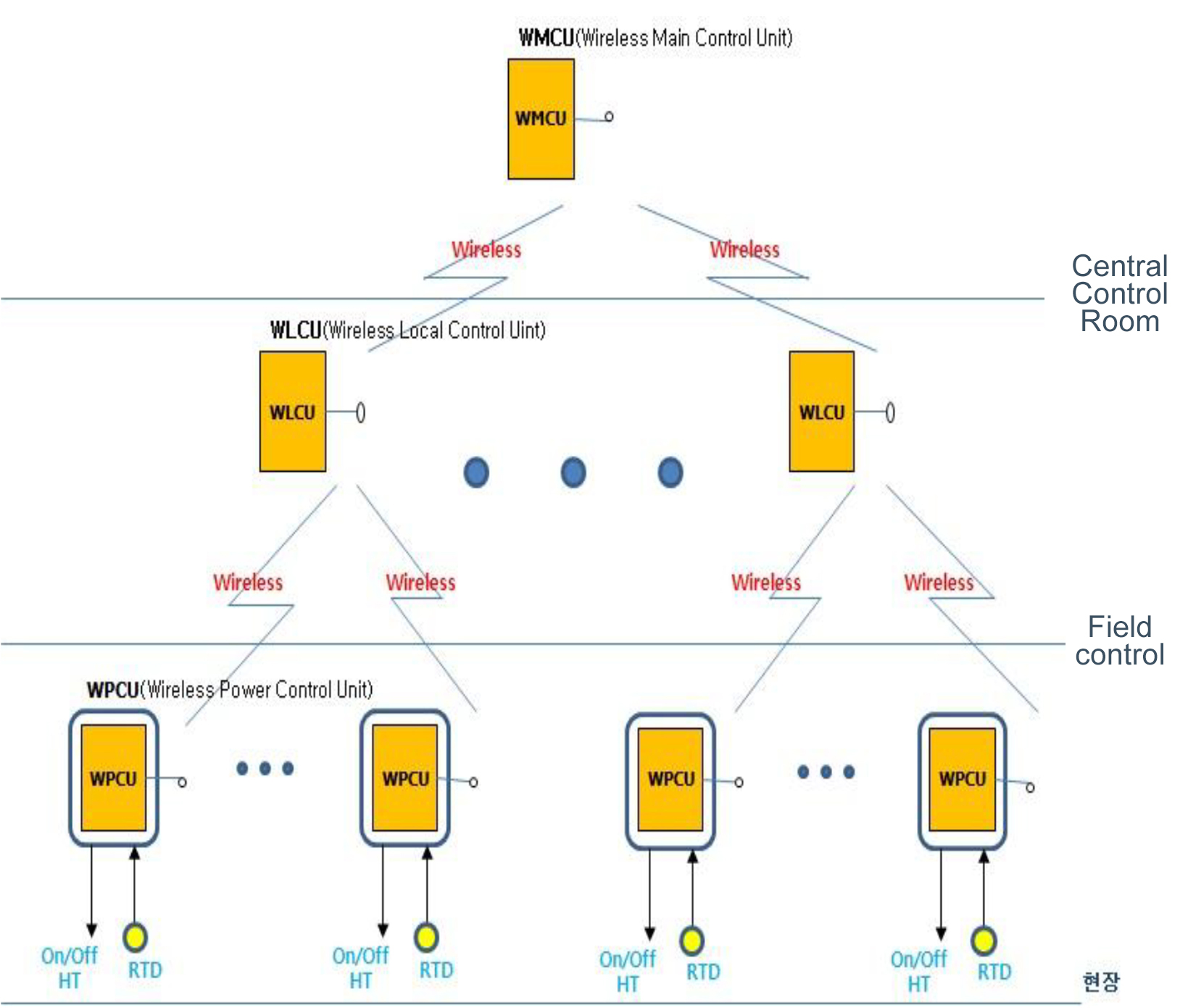

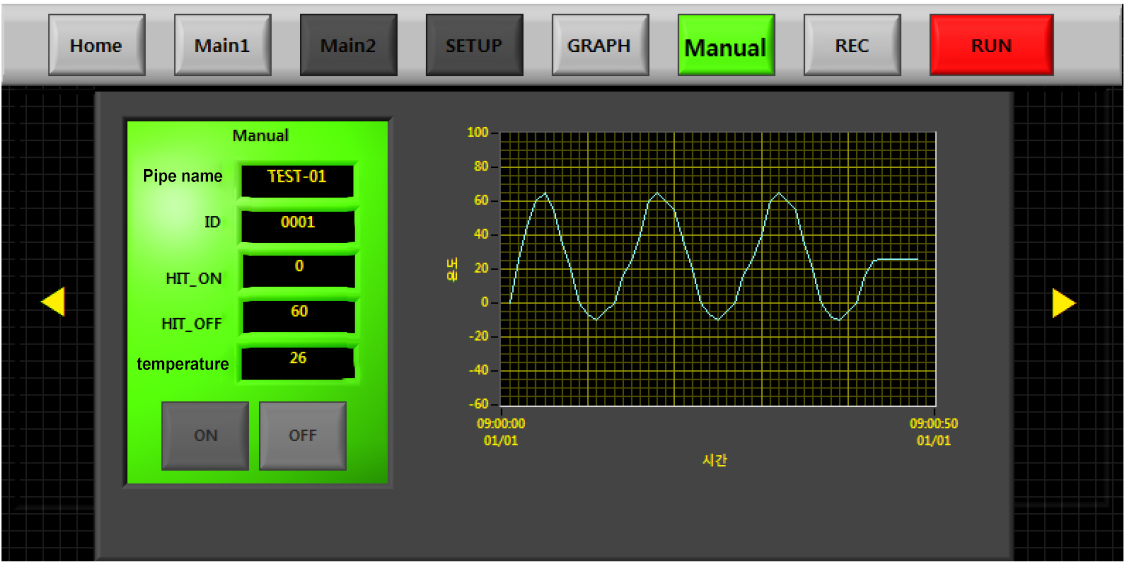

WFCU : Wireless Field Communication Units and IO Sensor Modules

- 1) Sensor for sites (Product in the marketplace) : RTD Pt 100Ohm (Multi-Sensor DC Level is being expanded and developed.)

- 2) Signal collector (Self-development) : Signal input and remote control output terminals, RF radio antennas, and LAN ports

- 3) Switch & PC (Product in the marketplace) : Switch Hub, Personal Computer

- 4) GUI program (Self-development) : Monitoring, recording, and analyzing remote control signals, control setting, and remote control

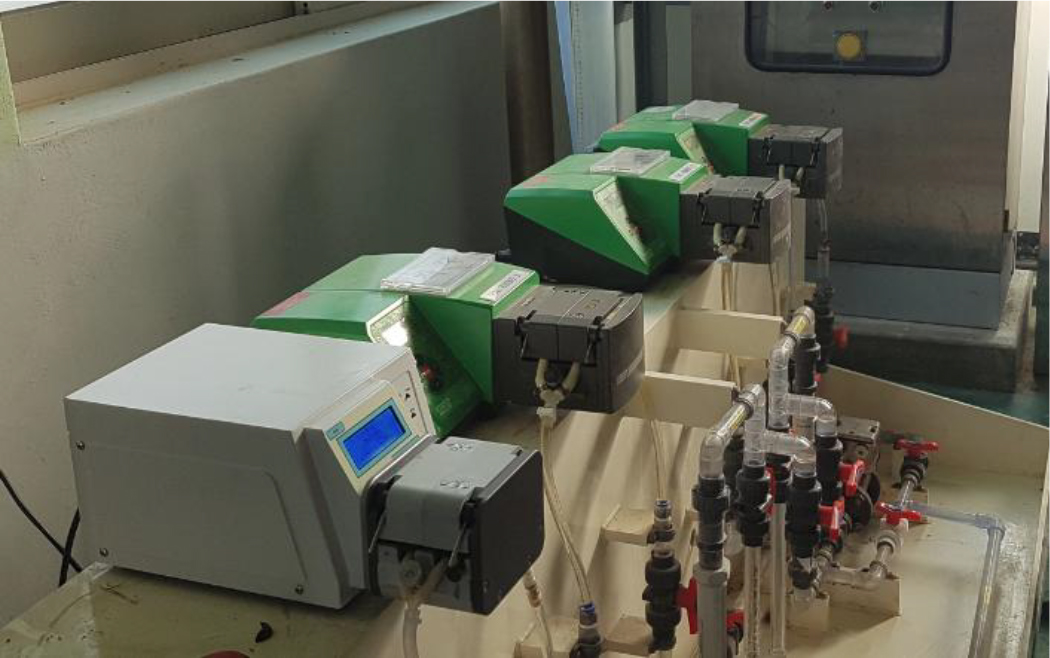

Tube Pump and remote control systems

- 1) Features : Can set remote inputs and is fitted with LAN communication systems for remote control.

- 2) Demanders : Industrial process required for corrosion resistance including all kinds of chemicals and control of inputting exact fixed quantities

- 3) Verification of commercialization : Verification of the proof test was completed in the site of K-water (As of November 2017)

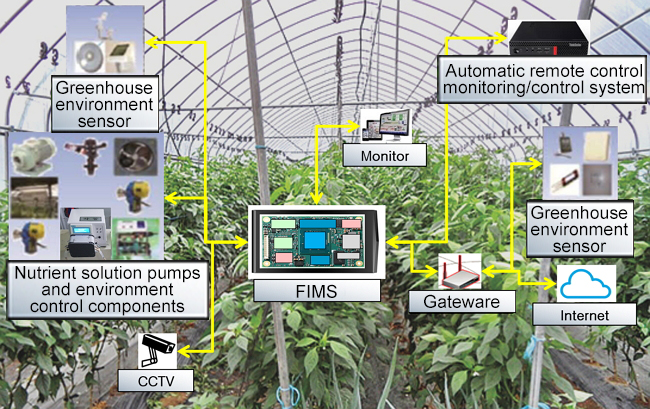

Smart farm

Smart farms

- 1) Promoting improvement of efficiency by collecting, processing, analyzing, or utilizing information in all value chains of agricultural production, processing, distribution, and consumption through the combination of agriculture with ICT technology

- 2) Improving the productivity and quality of crops by keeping optimal environment and controling nutrient solutions based on real time sensing information on the greenhouse environment and their growth condition.

- 3) Developing new varieties of crops that the outputs are kept or increase even though climates degrade.

- ① Technology which maximizes outputs through automatic remote control monitoring/control systems.

- ② Technology which monitors crops and manage and improve their management by using medicinal fluid pumps and environmental sensors.

- ③ Research and development of smart farm systems by integrating management system technology or agricultural technology with IoT/ICT technology in seeding, irrigation, harvest, and non-cultivation.

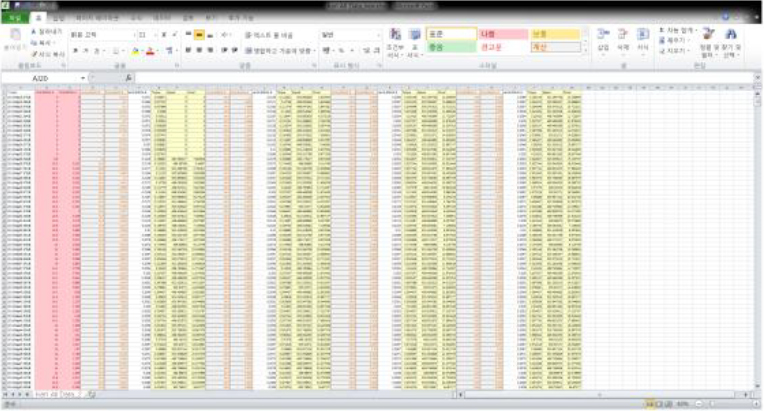

DAS/DAQ & performance diagnosis system

Vibration measurement and analysis system

- 1) Measuring and displaying vibration data of important facilities as the vibration measuring and analysis system.

- 2) Diagnosing and evaluating performance by analyzing vibration

- 3) Measuring and analyzing acceleration, speed, and displacement

- 4) User customized visualization work and output of the report forms

Wireless Electric Heat Tracing System

- 1) Electric Heat Tracing System Having the patent.

- 2) Wireless Communication Module

- 3) Pt-100 RTD Temperature Measurement

- 4) 220VAC Output SSR

- 5) Power Data Monitoring System

- 6) Self-Regulating

- 7) Analyzing performance and measuring efficiency.

- 8) Penal board with the remote communication function

Tube pump for controling fixed quantities

- 1) Low pulsation tube pump which modularized discharge flow rates exactly by remote control as the Korean tube pump which will replace imported tube pumps (Having the patent).

- 2) Speed : ~350 rpm

- 3) Pressure : 2~4 bar

- 4) IP rating : IP31

- 5) Precision : ±2%

- 6) Flowrate : ~1000ml/min

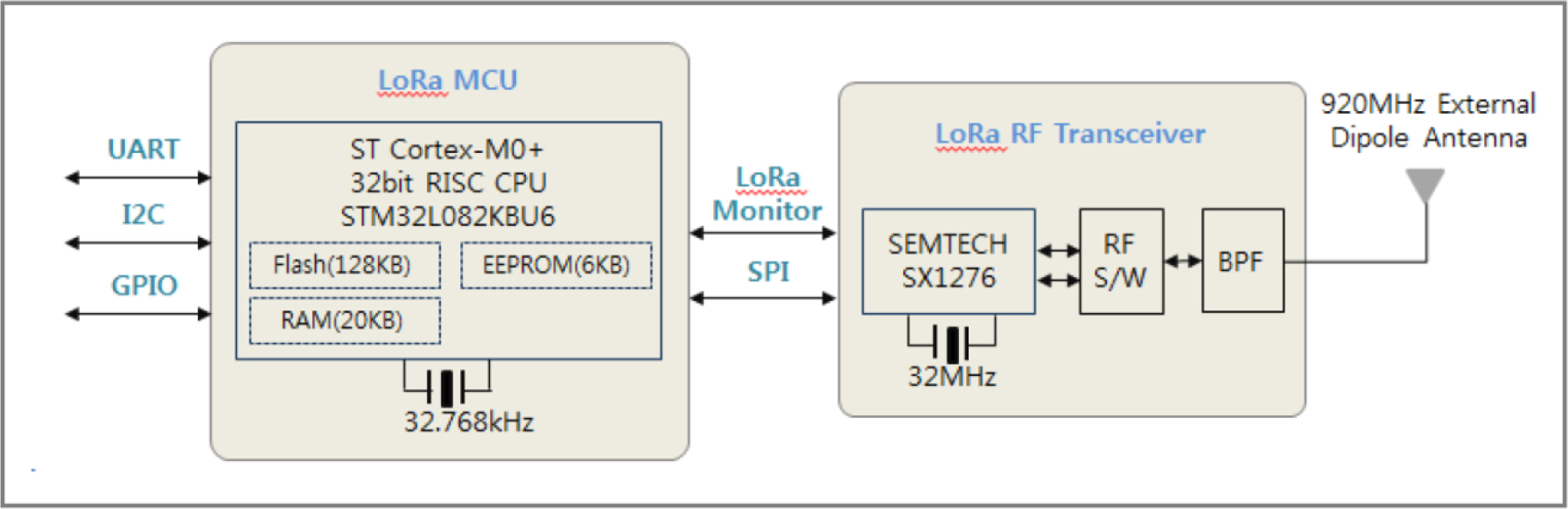

LoRa Module Wireless Communication based on LoRa Technology

- 1) Operating on 920MHz Unlicensed ISM band

- 2) AES 128-bit H/W Encryption Engine

- 3) Low Power Consumption MCU : Cortex- M0+

- 4) RoHS compliant

- 5) Various peripheral

- 6) 128KB internal Flash Memory

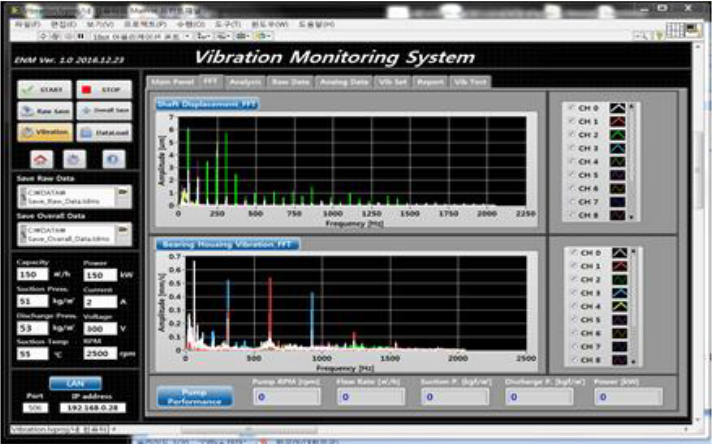

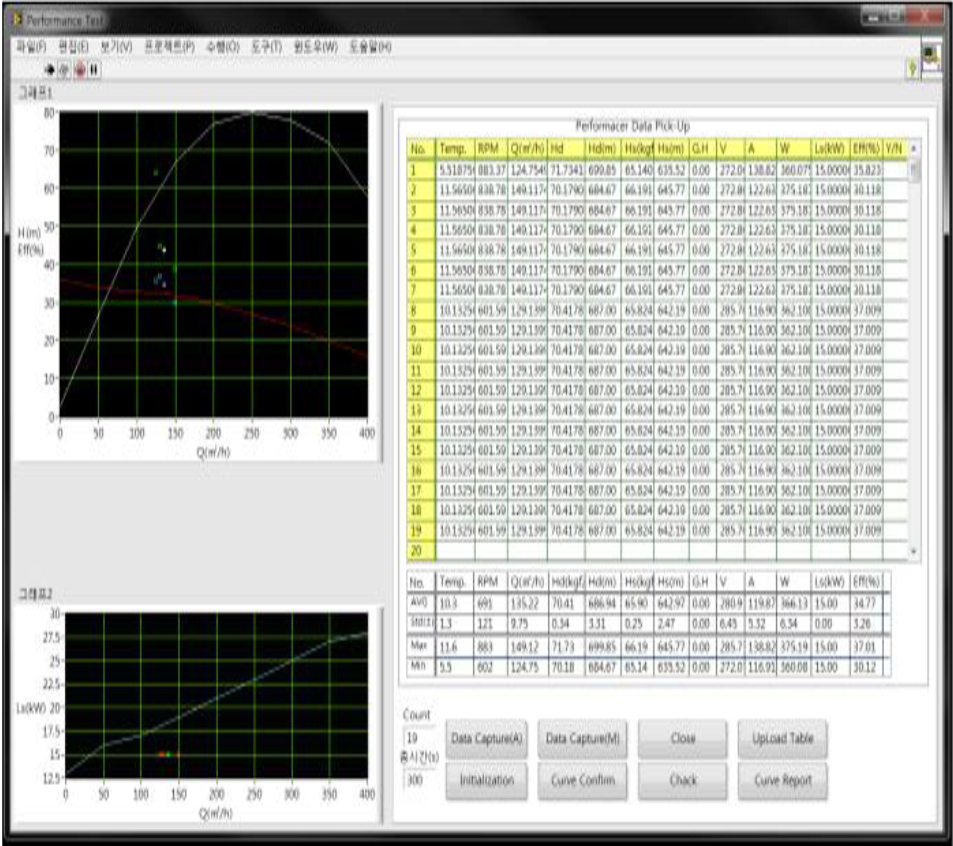

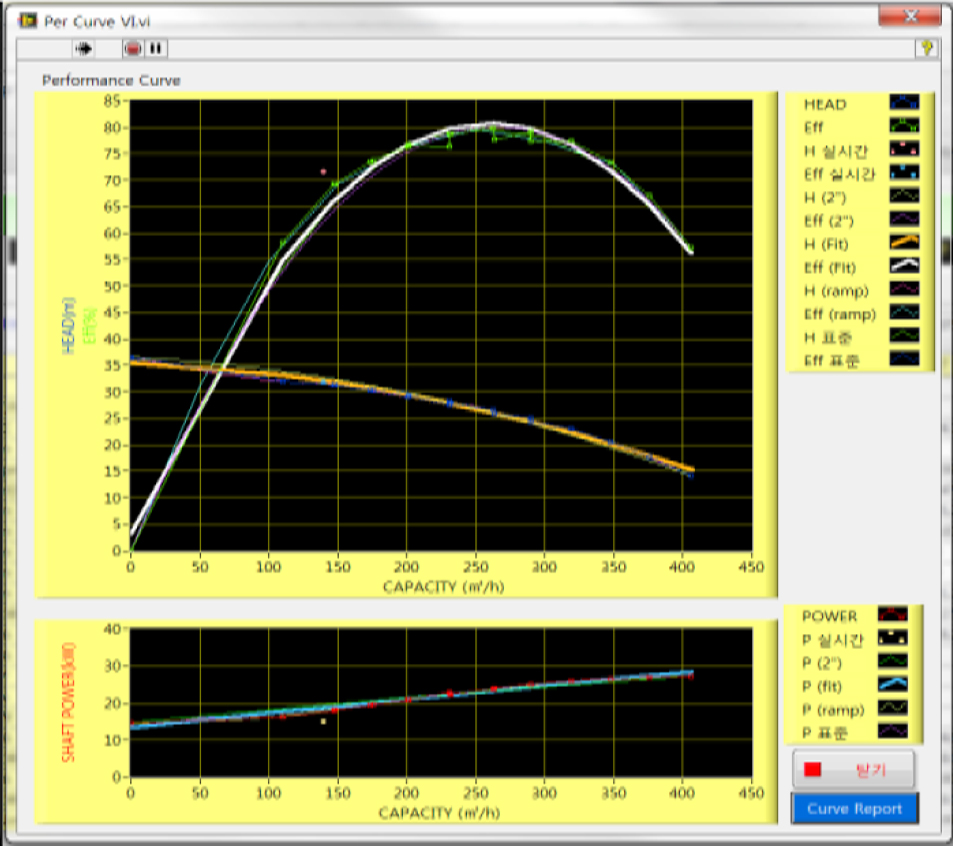

PTS(Performance Test System)

- Equipment component list :

- 1) Sensor in the sites: DC Level signals in flow rates, pressure, temperature, and liquid level sensors and AC Level signals in displacement, speed, and acceleration sensors

- 2) Signal collector: Self-developed products + Products in the marketplace

- 3) Switch & PC : Switch Hub, Personal Computer

- 4) PT program (Self-development): Monitoring, recording, and analyzing signals, making out all kinds of user customized reports, measuring energy efficiency, taking performance tests, and managing test DB.

- 5) Significant details : The number one and two world-class pump companies completed building this company's systems.

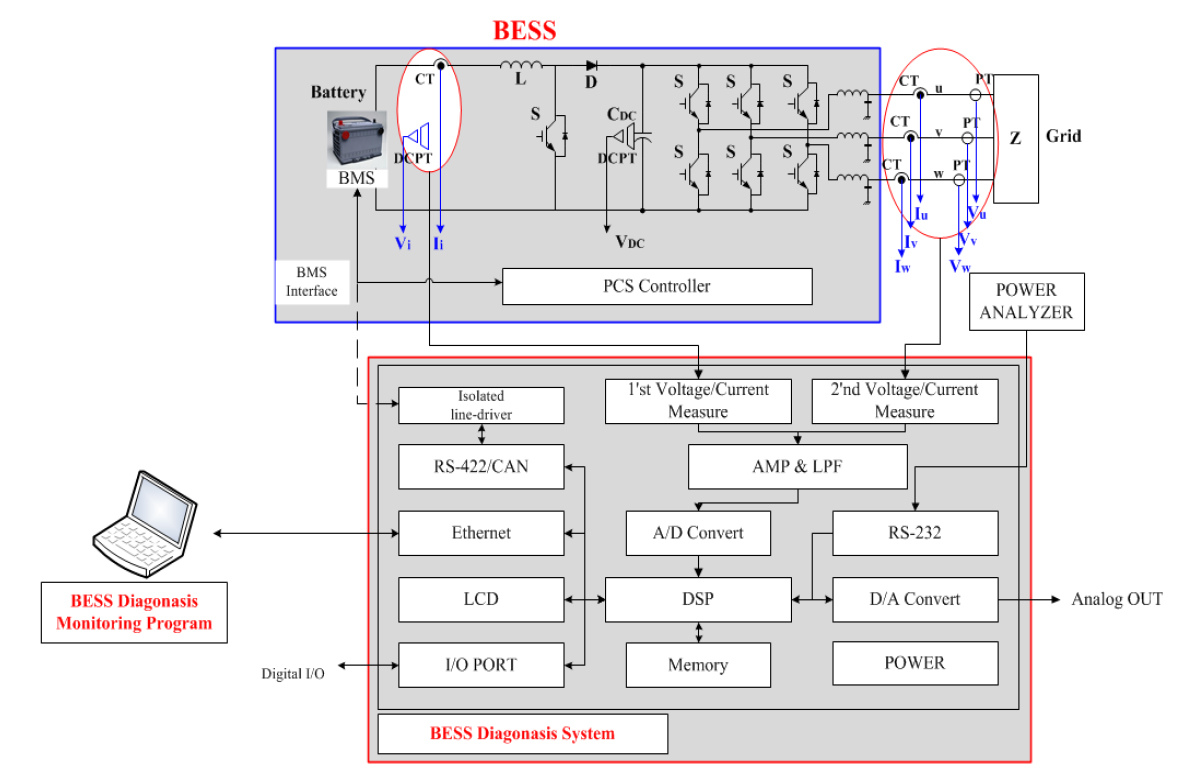

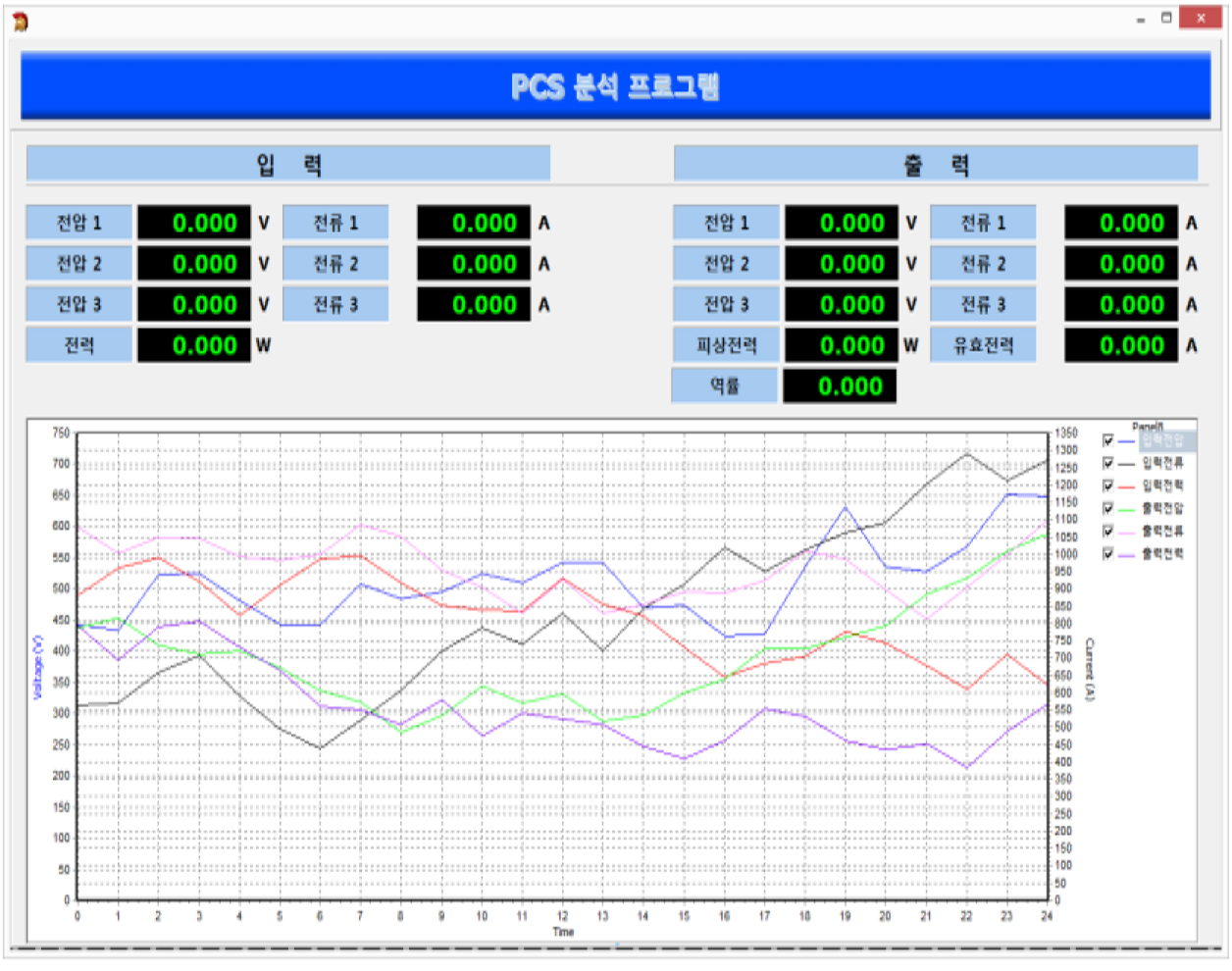

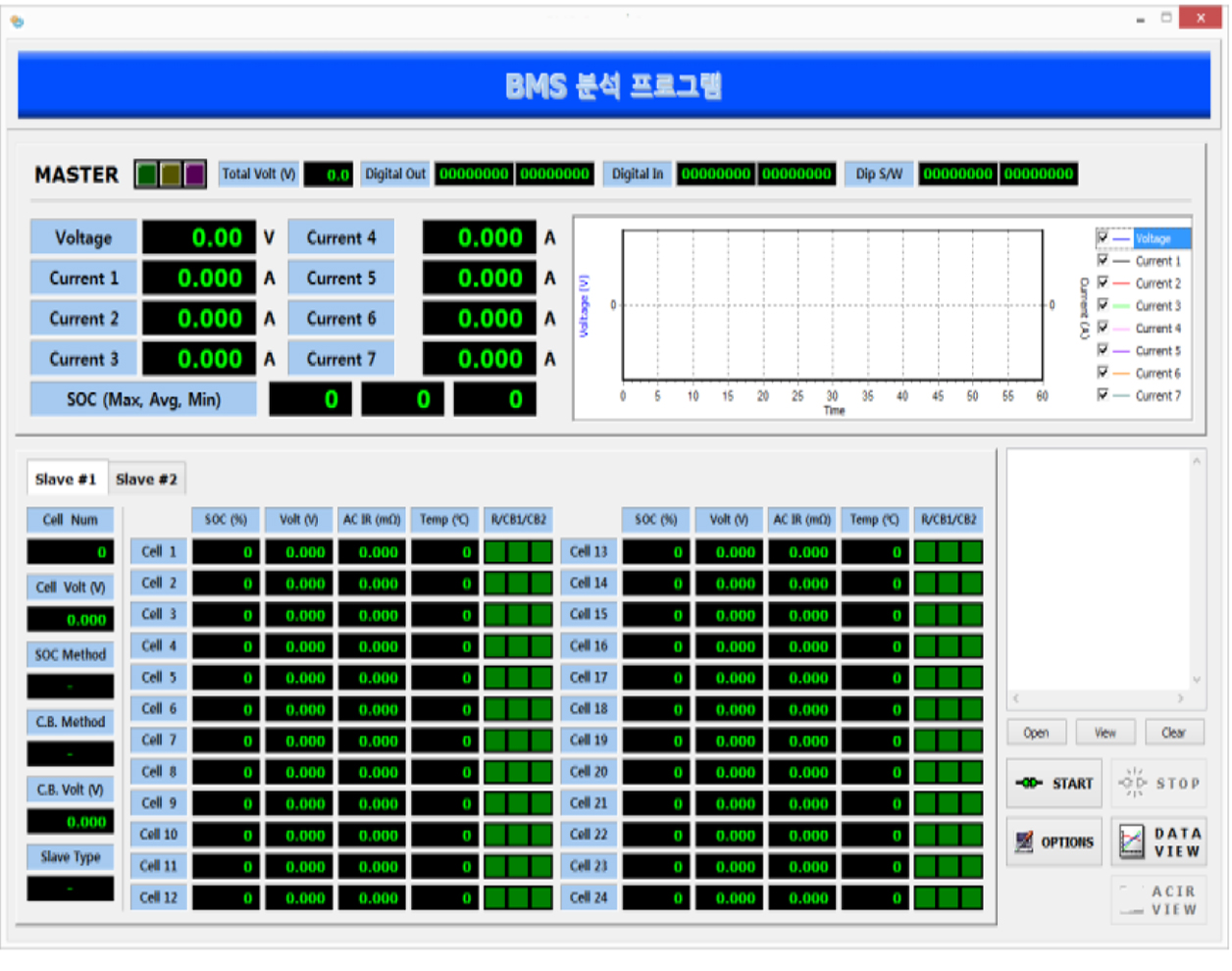

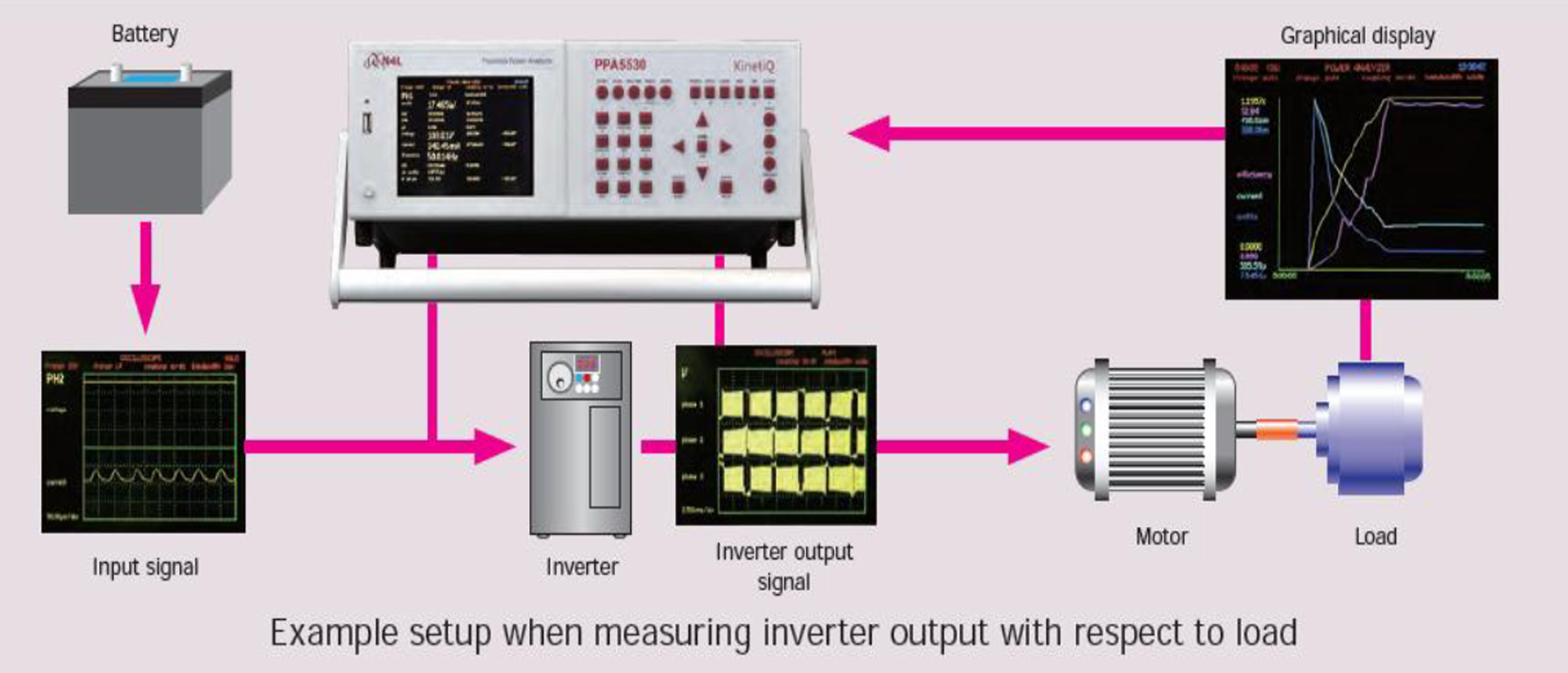

3kW BESS performance diagnosis system for family use

- 1) Measuring voltage and currents of input and output of PCS and analyzing its efficiency through the system to analyze and monitor BESS (Battery Energy Storage System).

- 2) Sending and receiving all kinds of data by communicating with BMS (Battery Management System) for family use and diagnosing the BMS state.

- 3) It is easy to carry the BESS analysis system and it monitors data by accessing to it in remote places.

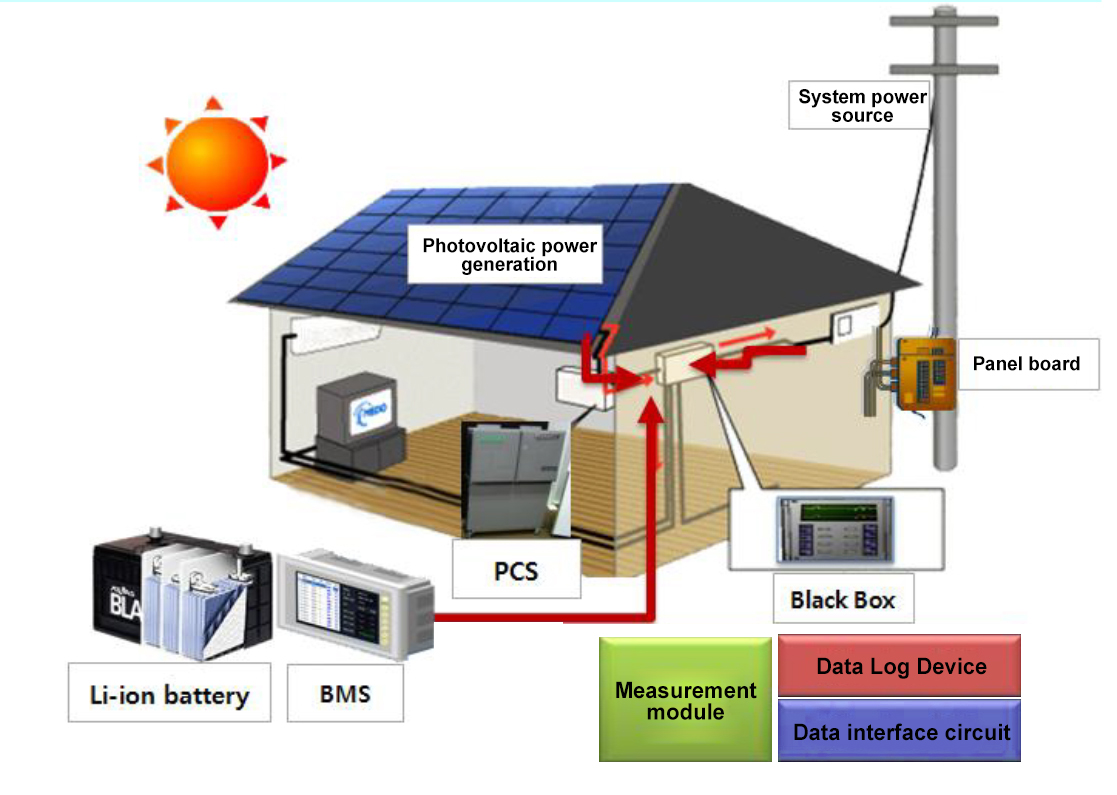

10kW BESS performance diagnosis system for family use

- 1) Providing data which analyze causes of failure by measuring and saving all kinds of conditions and diagnosis data of system power sources and photovoltaic power generation.

- 2) Increasing user convenience and securing the absolute safety by providing status alerts of the state saved in black boxes and diagnosis data for users through GUI-based monitoring programs and mobile apps.

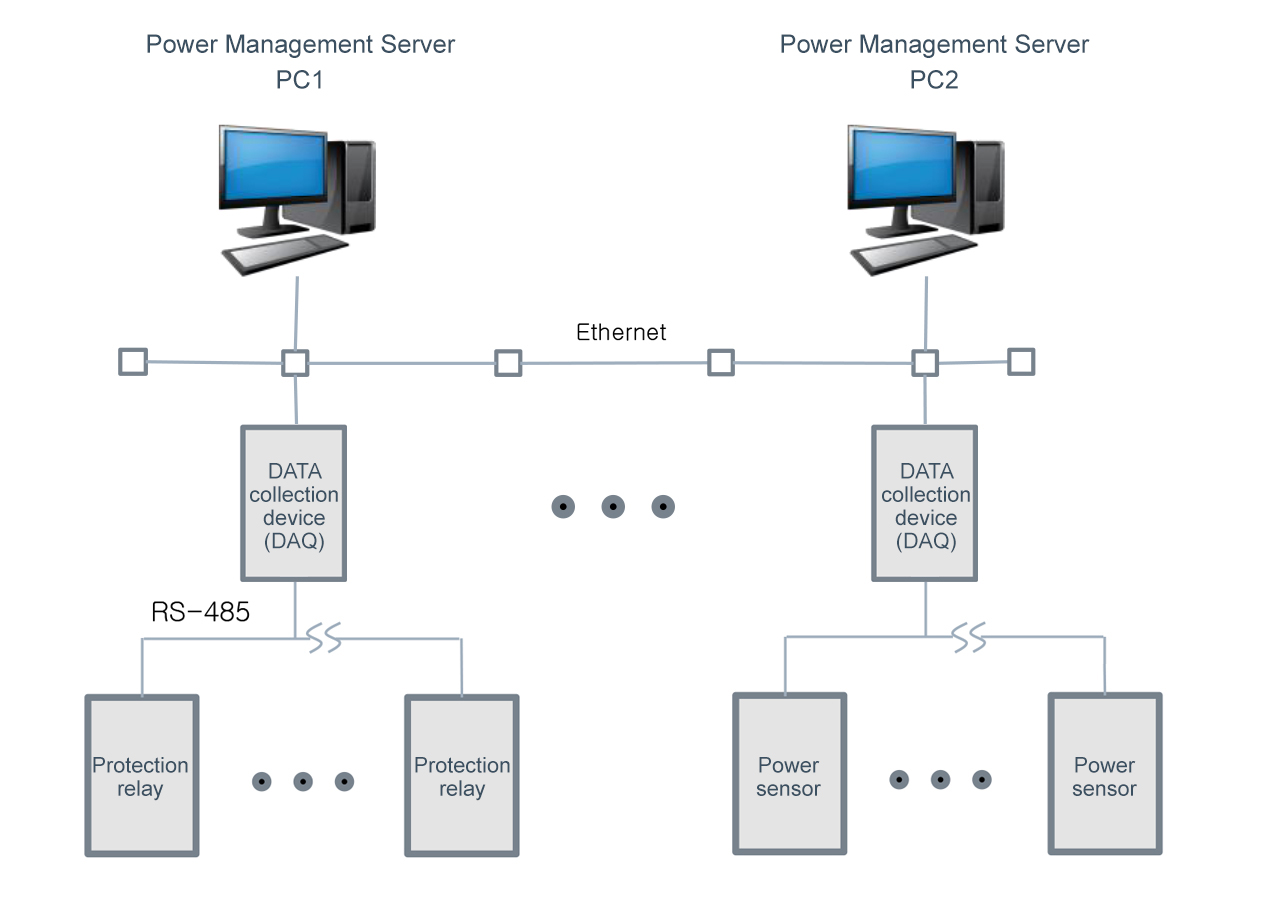

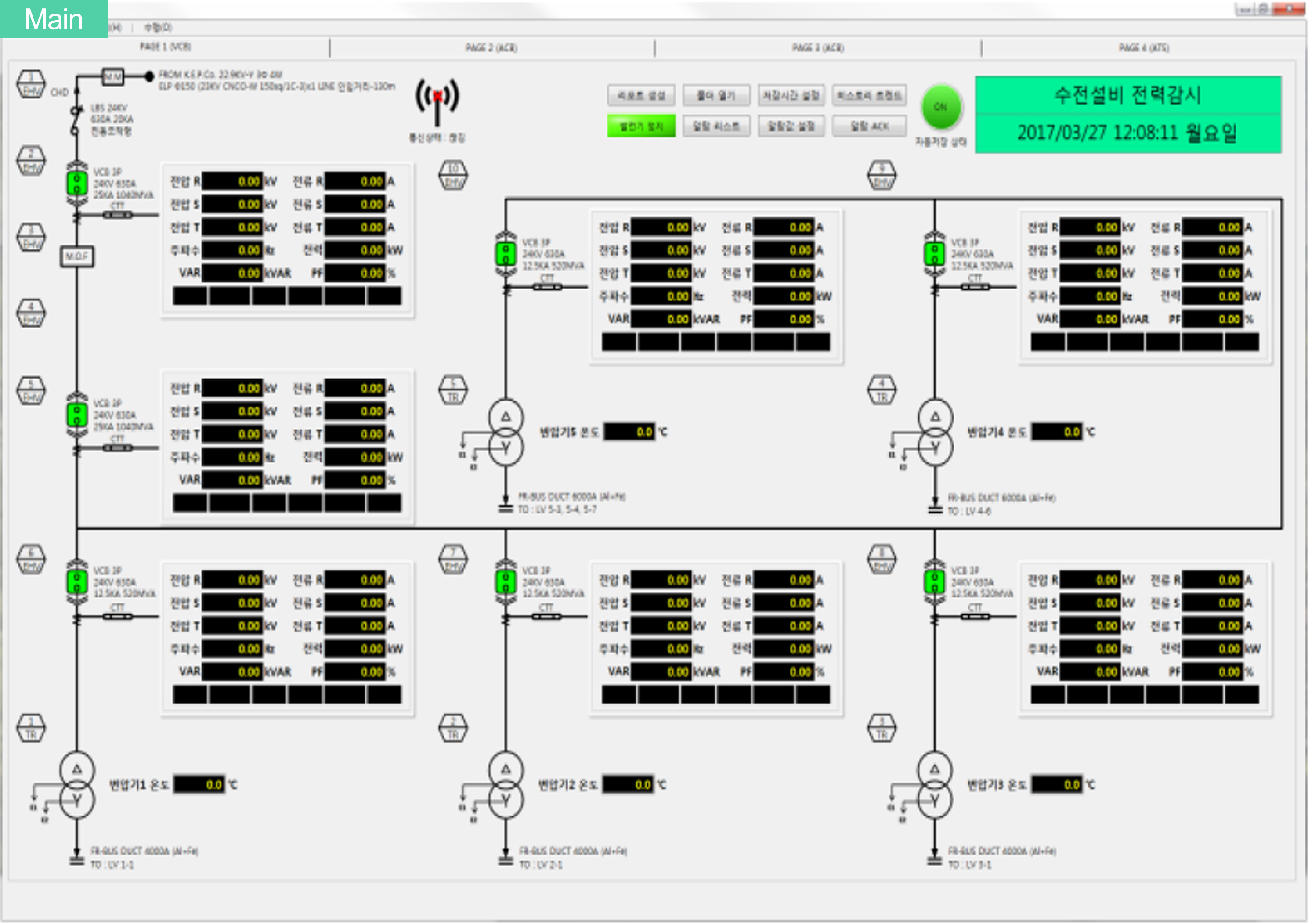

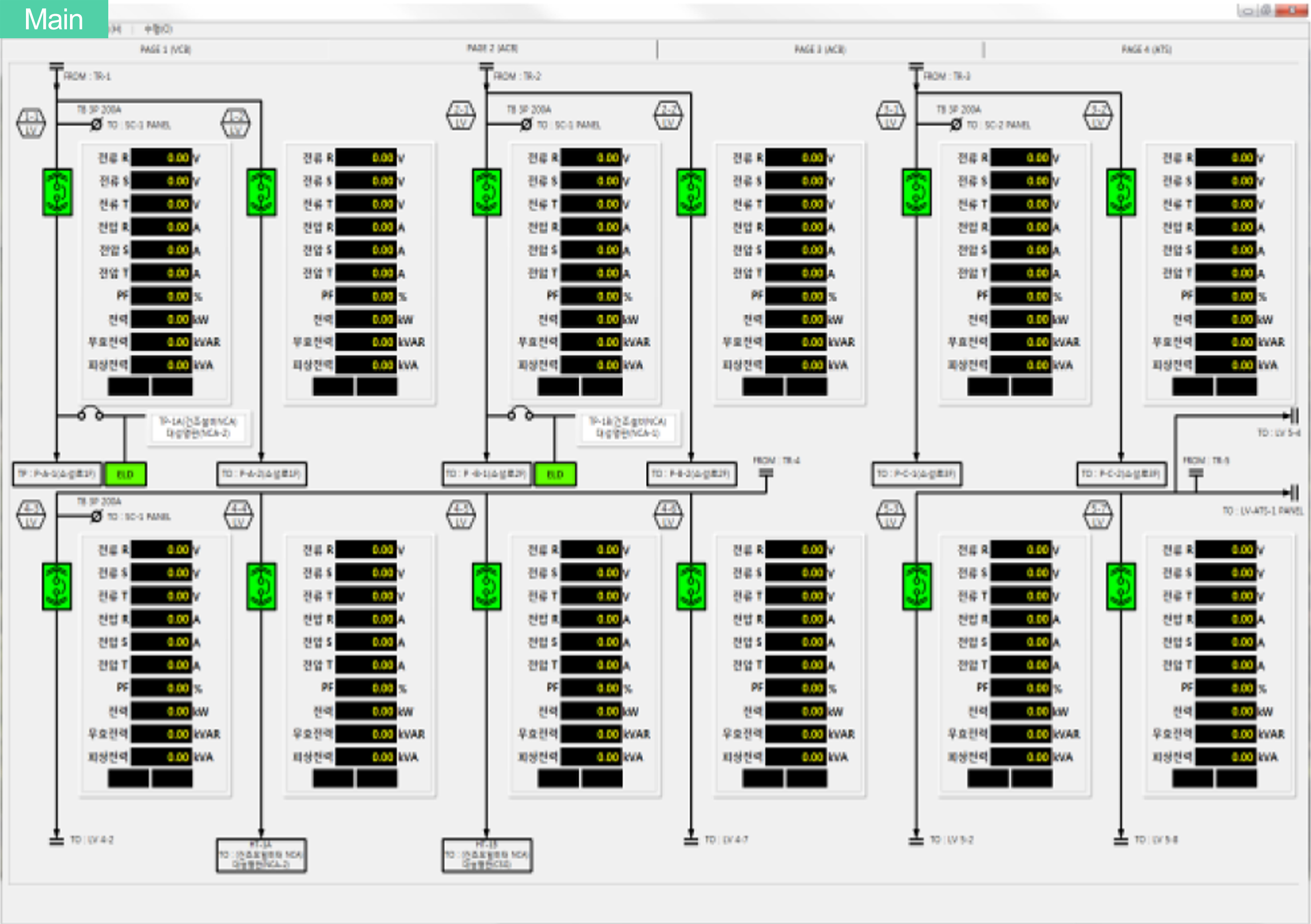

PIPMS(Power Integrated Platform Management System)

- Users monitor and manage the current status by analyzing power usage and monitoring relay factors.

- Quick actions can be done when problems arise and power can effectively be used by checking DATA.

- 1) Composition

- ① Sensors to collect DATA in the sites

- - An electronic protection relay for distributing boards

- - An electronic electric power sensor for panel boards

- ② PC which monitors collected DATA

- ③ Communication method : Sensor : RS-485

-

- 2) HMI (The screen for users in the power monitoring system)

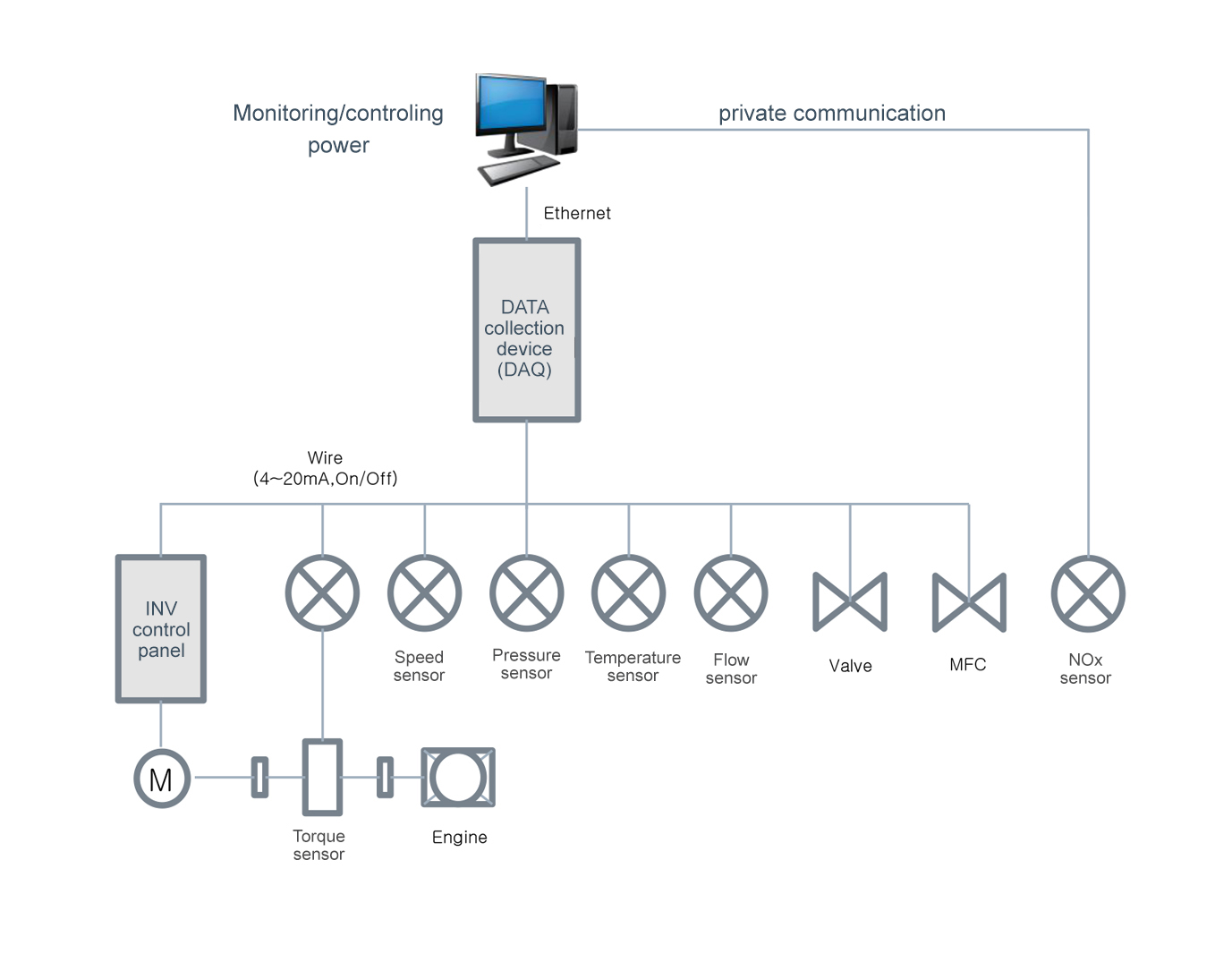

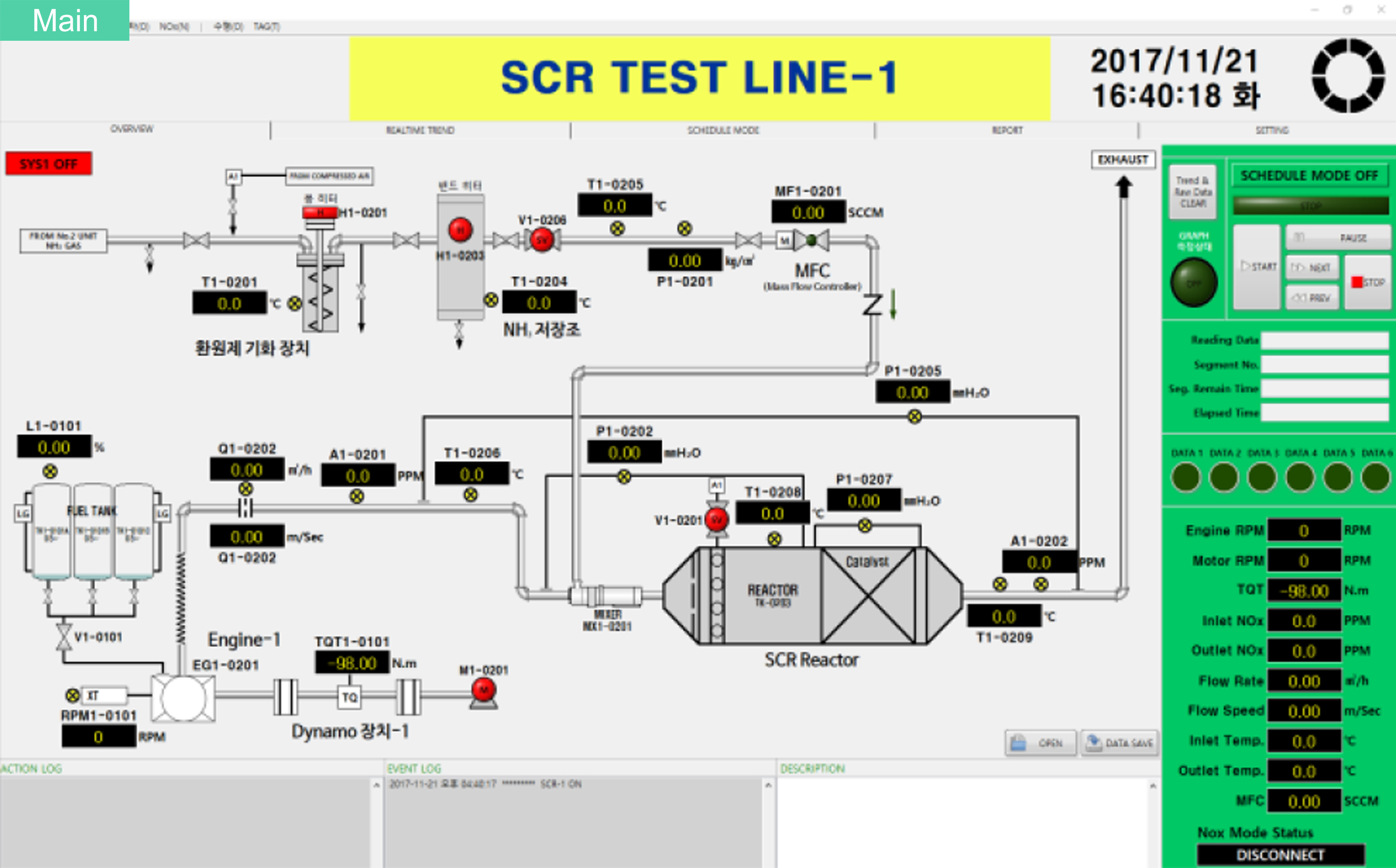

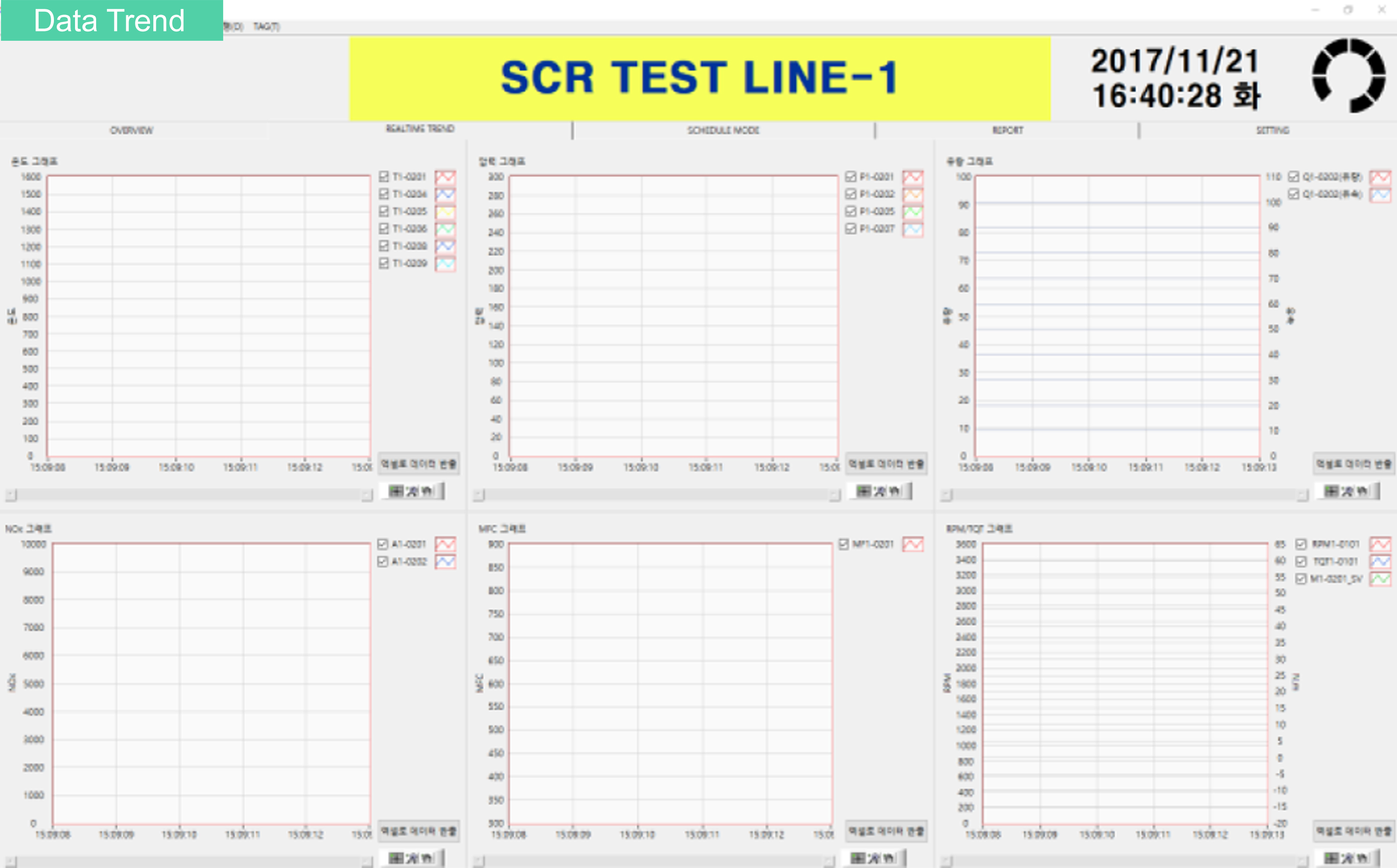

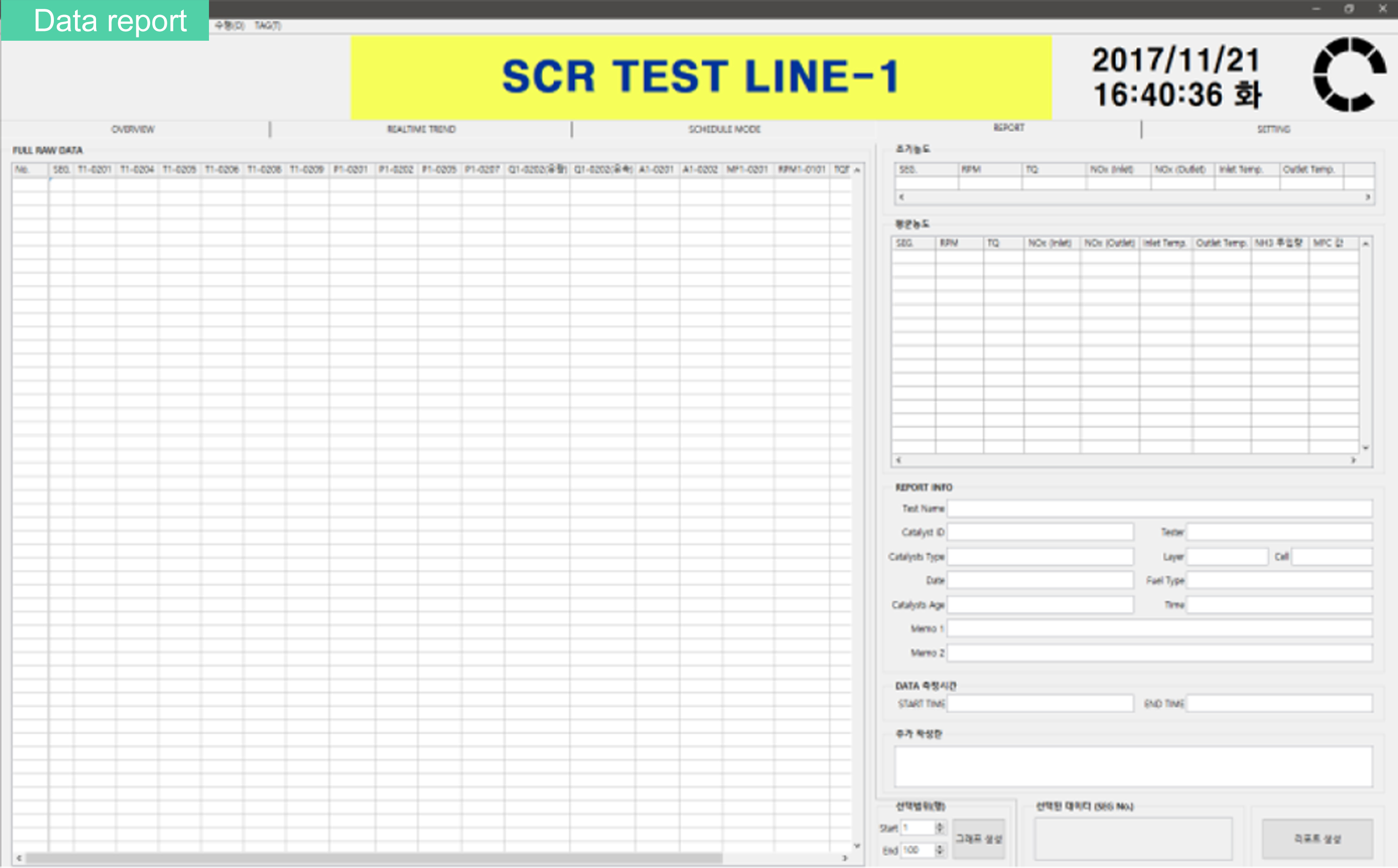

Device for testing the durability of DYNAMO and SCR

- Measuring and evaluating Torque, Output Power, and Speed in real time as the engine test by a motor.

- Device which tests the durability of SCR by spraying ammonia on a exhaust gas pipe of an engine to remove nitrogen oxide in exhaust gas through a NOx sensor in it.

- 1) Composition

- ① Consisting of a DYNAMO testing device of a motor

- ② De-Nox SCR testing device(NH3 spray, MFC, NOx, temperature, pressure, flow sensors, etc.)

- ③ DATA collection and control device

- ④ PC for monitoring/control

- 2) HMI (Dynamo & SCR)

Manufactured products

- 1) Performance test and diagnosis equipment of machines

- 2) Manufacture of all kinds of instrumentation Panels, Consoles, and TM/TC RTUs

- 3) Manufacture of network equipment

- 4) Manufacture of Lube Oil Units and oil pressure control systems

- 5) Manufacture of vacuum and control panels

- 6) Manufacture of volumetric pumps and control panels

- 7) Manufacture of devices for collecting and analyzing vibration signals

- 8) Manufacture of panel boards for radio electric heating systems and radio remote control devices

- 9) Maintenance, inspection, and comprehensive installation construction

Measuring instruments, analyzers, electrothermal wire

pumps and valves, and oil pressure machines

Selling agents

- 1) All kinds of process meters including flow rates, pressure, temperature, or water gauges

- 2) Mechanical diagnosis meters including vibratory machines and acoustimeters

- 3) Power analyzers and dynamometers

- 4) Heat Tracing Material

- 5) Industrial pumps, vacuum pumps, and valves

- 6) Lube Oil Unit

- 7) Oil pressure machines

Motor performance diagnosis system

- 1) In-operation_General diagnosis

- Measuring appearance, bearings, temperature increase, vibration, damage of rotor bars, unbalance of power supply, axle voltage, and iron concentration of bearings.

- 2) In abeyance _ Precision diagnosis (High pressure AC motors)

- Insulation resistance measurement, direct current tests, alternating tests, dissipation factor tests, partial discharge tests, wire wound resistance measurement, and visual inspection

- 3) In abeyance_ Precision diagnosis (DC motors)

- Insulation resistance measurement, direct current tests, capacitance tanδ measurement, commutator wobble check, drop tests among commutator bars, checking abnormality among commutator bars, checking neutral points, and visual inspection

Head office and factory : 706, 16, Heungan-daero 427beon-gil, Dongan-gu, Anyang-si, Gyeonggi-do, Republic of Korea

Research Institute: F2, 180-4, Sadang-ro, Dongjak-gu, Seoul, Republic of Korea

Tel : 02-585-6040 Fax : 02-585-6041

E–Mail : enm21@daum.net

Research Institute: F2, 180-4, Sadang-ro, Dongjak-gu, Seoul, Republic of Korea

Tel : 02-585-6040 Fax : 02-585-6041

E–Mail : enm21@daum.net